Palladium, rhodium, and platinum are examples of precious metals that are essential to many sectors, including electronics, jewellery, and the automobile industry. Nevertheless, mining operations frequently extract these priceless metals from limited stocks, making them finite resources. By reclaiming precious metals from waste sources, recycling provides a sustainable substitute by extending their useful life and lowering the demand for new mining. The journey of precious metals recycling from trash to resource will be discussed in this article.

1. Gathering of Scrap Materials

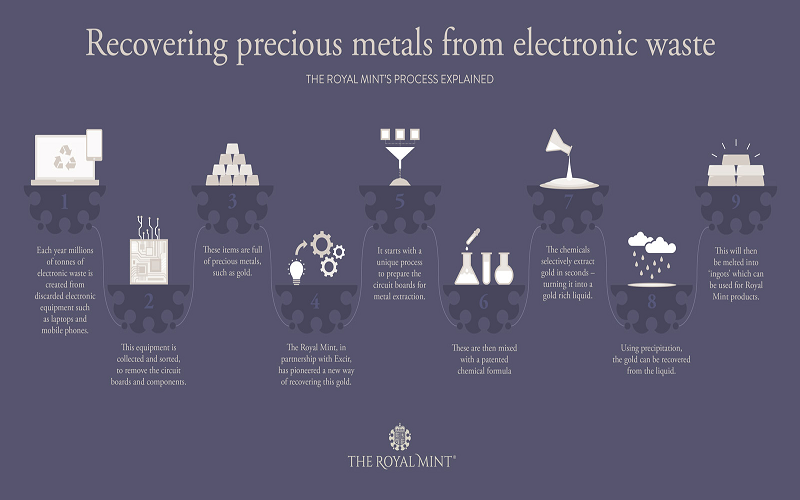

The process of turning waste materials like old catalytic converters, electrical parts, and jewellery into valuable metals starts here. Recycle facilities, electronic garbage, and end-of-life cars are the sources of these elements. Scrap collectors are essential to collecting these items and transporting them to recycling facilities for processing.

2. Processing and Sorting

After being gathered, scrap is processed and sorted to remove precious metals from other materials. For instance, the substrate containing precious metal catalysts is retrieved from catalytic converters once the outer shell is removed. Circuit boards and connections that contain valuable metals are recovered by disassembling electronic garbage. In order to maximise metal recovery and guarantee the quality of recycled materials, this sorting and processing step is essential.

3. Chemical and Mechanical Processing

Scrap materials are sorted and processed chemically and mechanically to recover valuable metals. Metals are removed from substrates and electronic components by chemical processes, including solvent extraction and leaching. Materials are broken down by mechanical techniques like crushing and shredding so that the metals may be extracted. For these procedures to be successful and economical, specialised tools and knowledge are needed to extract metals.

4. Refining

After being extracted, the precious metals are refined to get rid of impurities and reach high purity levels. Refining techniques might involve electrolysis, distillation, or precipitation based on the kind of metals being extracted. Refinement guarantees that recovered metals are acceptable for a variety of uses and fulfil quality criteria.

5. Reuse and Repurpose

Then, recycled precious metals may be used again to create new goods. Recycled platinum, palladium, and rhodium are used in the automobile industry to create new catalytic converters, which lowers the need for virgin materials. Recycled metal is also used in the electronics industry to make new parts, circuit boards, and connections. To produce new designs, jewellery makers also employ recycled gold, silver, and platinum, which promotes sustainability in the luxury goods sector.

6. Economic and Environmental Advantages

Precious metals have several positive effects on the environment and the economy along their path from trash to resource. Recycling lessens the negative effects of mining on the environment, including greenhouse gas emissions, habitat damage, and water pollution. By prolonging the life of limited deposits, it conserves natural resources and utilises less energy than producing virgin metals. Recycling also boosts economic stability and prosperity by adding jobs to the recycling sector.

In Summary

The path taken by precious metals from trash to resource highlights how crucial recycling is to the preservation of natural resources, the mitigation of environmental damage, and the advancement of sustainability. Precious metals are given a new lease of life through the gathering, sorting, processing, refining, and reuse of scrap materials, therefore supporting a variety of sectors and reducing the need for new mining. We can make sure that precious metals continue to improve our lives while protecting the environment for coming generations by adopting recycling methods and advocating for a circular economy.