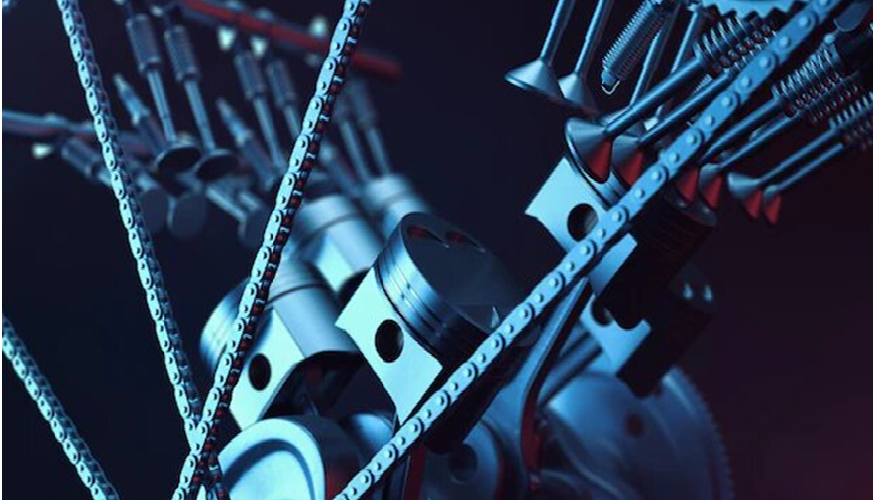

The clearance in the piston is the space between the piston and the metal cylinder, which prevents the piston from expanding excessively when heated. It is also called a clearance between the piston and the hole in the rod.

The piston is made of cast aluminium alloy in most cases because it is good at transferring heat.

When the metal cylinder is heated, aluminium grows more than the metal. Therefore, they need enough space to keep the pistons moving freely in the cylinder, they need enough space. The Piston ring manufacturers in India understand the clearance techniques that make the piston rings long-lasting.

The air-fuel mixture for the Otto cycle or air for the diesel cycle is squeezed together. This happens when the piston reaches its TDC point during the compression stroke. There is not a need for absolute zero clearance, though, because the mixture needs its own space or volume to live.

There are four different types of clearance in pistons. Keep reading below to know each of them and their roles in the piston ring.

● Axial Clearance

The clearance between the ring’s top and the groove will be measured with a feeler gauge. This clearance needs to be checked at four different places for each ring to ensure it is correct. The Piston ring manufacturers in India understand that the clearance is monitored and working as required.

● Radial Clearance:

Radial clearance can be calculated using Vernier callipers. The radial clearance is the difference between the groove depth and the ring width.

● Butt Clearance

Putting Prussian blue paste on the butt ends of your finger will make a picture of the ring. You can measure the gap to determine how far apart the impressions are.

● Controlled Pressure Relief Groove Measurement Ring:

The CPR ring is put in the main piston. It is used to control the amount of pressure that can come out. The CPR ring has an S-shaped butt joint with six controlled pressure relief grooves milled into the surface of the ring face. It is essential to measure how far apart each groove is from the S joint so that your butt is not stuck.

Soon after the spark is made, the mixture wants to expand entirely in this small space at high pressure and temperature, which is not big enough for expansion. This causes the piston to move down, which causes the power to be made.

Piston rings, wiper rings, and oil rings are three piston rings used in small engines. The piston ring is in the ring groove near the piston head. Compression makes sure the combustion chamber does not leak while making electricity or gas. Combustion gases push the head of the piston, causing it to move closer to a crankshaft.